Internal Combustion Engine Filtration (Air, Oil, Fuel)

Every vehicle, machine or

boat with an internal combustion engine, whether it is used on or off the road,

has a number of filters. These various filters are crucial to the durability

and performance of the engine. Filters are responsible for preventing

impurities carried by air and fluids from entering the engine. Quality

filtration and regular maintenance are therefore necessary to ensure the

performance and life of the engine.

Are you looking for the best

engine filters? Filtration Expert will

help you providing all possible filtration solutions for the maintenance of any

engine.

Air Filter: A vital part of the engine

The air filter is an essential part of the engine, preventing particles of dust, sand, carbon or other foreign matter in the air from entering the engine intake system. By blocking these impurities, it protects the rings, pistons, liners and turbocharger from premature wear and extends the life of the engine.

The air filter also ensures that the engine's performance is maintained thanks to an optimum supply of oxygen, which is necessary for the proper combustion of the fuel.

Importance of fuel filters

Every combustion engine is equipped with one or more fuel filters to ensure protection of the engine components concerned and their optimal functioning. Modern diesel engines incorporate high pressure direct injection systems (over 2,000 bar), known as Common Rail, in order to comply with CO2 emission regulations. These modern but sensitive injection systems require ever finer filtration to avoid breakdowns.

Water in the fuel and condensation in the tank can cause seizure of the injectors and lead to corrosion damage. A well-maintained fuel system extends the life of your engine, improves its performance and reduces fuel consumption. Effective fuel filtration and appropriate separation is therefore necessary to prevent these risks and ensure long-term engine performance.

Engine oil filter

Oil is a central element in the operation of an internal combustion engine, lubricating the moving parts and thus preventing premature wear and irreversible damage to the engine. To ensure long-lasting and optimal protection, it must remain clean at all times thanks to effective filtration that retains dust, metal abrasion particles and combustion residues.

By

separating these contaminants from the oil as it travels through the system,

the oil filter ensures the engine's longevity and performance. It is therefore

essential to choose a quality filter with a high retention capacity and to

replace it regularly at each oil change.

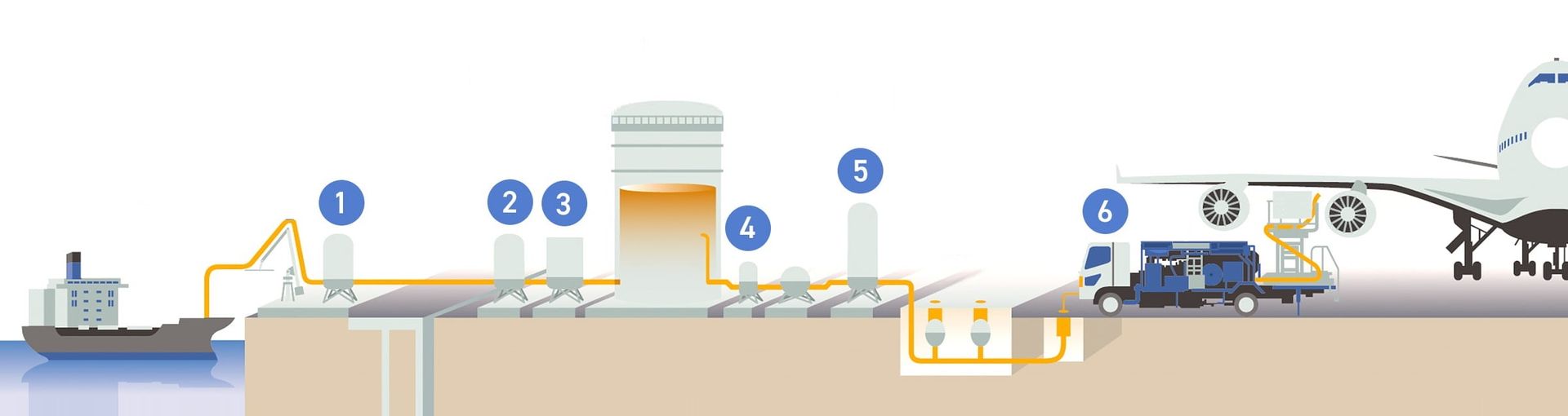

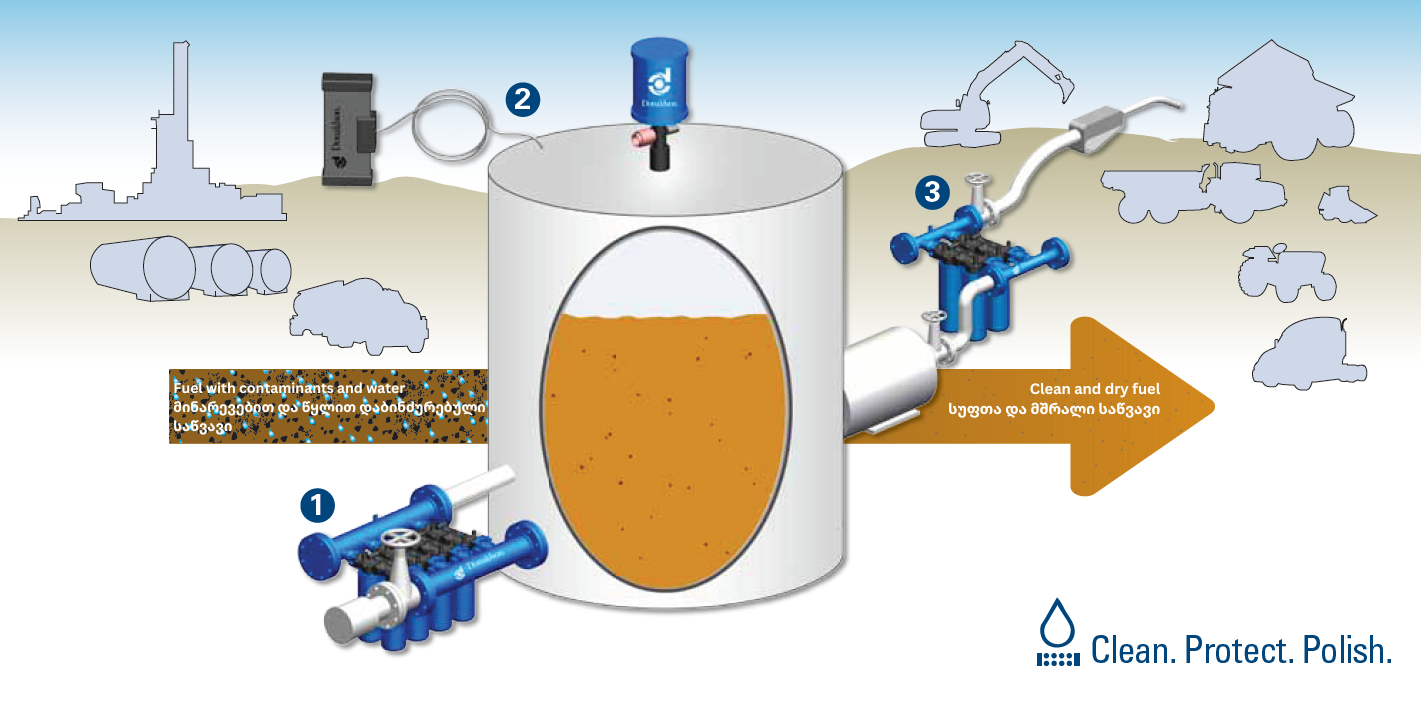

Fuel Bulk Filtration Systems

In order to get the fuel from the oil refineries to the point of your final use, it has to change several transport vessels on the way. This multiplication of transition phases increases the risks of fuel contamination with impurities, water and bacteria. Whether it is particulate, bacteria, water or condensation, build-up of contaminants can cause wear and corrosion of engine expensive components and electrical injection systems, leading to an increase in fuel consumption and eventually engine failure.

To

limit these complications, it is important to implement complementary and

effective filtration solutions during fuel delivery, storage and distribution.

The best solution for protecting high-performance electric injection systems of

modern engines, as well as your fuel storage reservoirs from contamination and

corrosion, is to filter the fuel transfers with a special Bulk Fuel Filtration

System.

Hydraulic Filtration

Whether for mobile equipment or industrial equipment, fluid quality is a critical component of hydraulic system reliability. Particulate contamination or the presence of water in the oil is the single most important cause of failure and breakdown in these systems. Therefore, filtration plays a vital role in their proper operation.

To maintain its properties and performance, the oil in the system must be thoroughly filtered. This filtration separates and blocks impurities, water and abrasion residues. This is particularly important when the equipment is used in demanding and dusty environments. These contaminants pose a real risk to hydraulic systems and most often lead to lubricant degradation, premature wear and reduced performance.

Compressor Filtration

Air/oil and condensate separation play a

crucial role for compressor applications.

Compressor oil becomes a source of contamination as it mixes with the air during the compression process. The installation of quality air/oil separator filter is therefore necessary to capture the oil particles and return them directly to the compressor oil circuit. As a result, the quality of the compressed air sent to the network is safeguarded and oil consumption is limited.

Condensate is an unavoidable result of air compression and is a mixture of water and oil particles. Such oily liquid must never be discharged into the wastewater system without first being filtered by condensate separator filter.

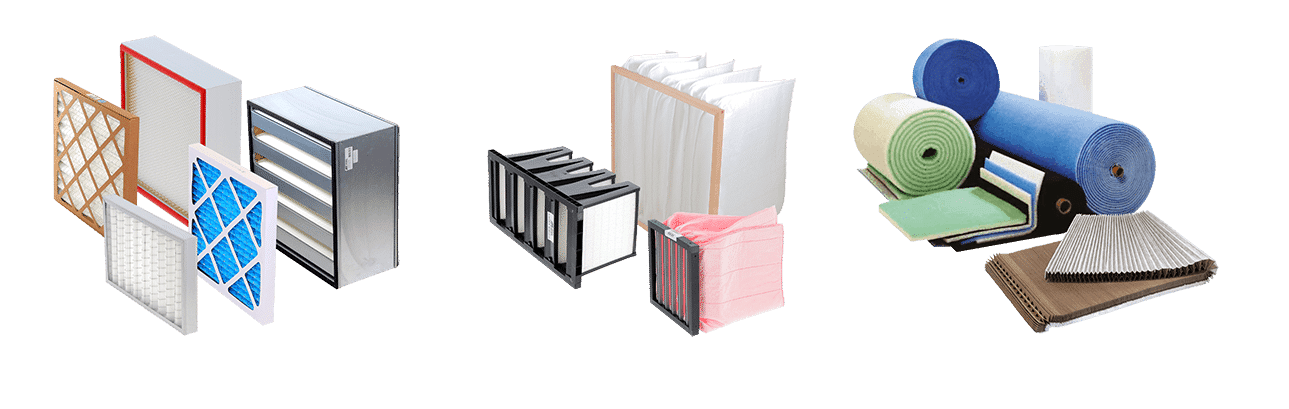

Ambient Air Filtration, HAVAC & HEPA

Filtration for ventilation, air conditioning and heating - Commercial, industrial and residential premises must provide high quality indoor air to meet three main protection challenges: of people, environment and manufacturing processes. Indeed, air pollution due to dust, fine particles, pollens or even bacteria and viruses can cause serious harm. For health, environmental and economic reasons, it is therefore essential to rely on efficient air filtration systems. Compliant with ISO 16890-1 and EN 1822: 2009, our ventilation, air conditioning and heating filters are available in a wide range of filtration classes to effectively combat all kinds of contamination. HVAC filters are available in various designs: media rolls, panel filters, bag filters, compact filters, absolute filters, activated carbon filters...

Clean room Filtration - In the medical, pharmaceutical, chemical, cosmetics and precision electronics industries, working environments must be strictly controlled (particle levels, air contamination, temperature, pressure, humidity, light, etc.). The HEPA-ULPA filters in our range meet the requirements of clean rooms by preventing particulate and microbial contamination.

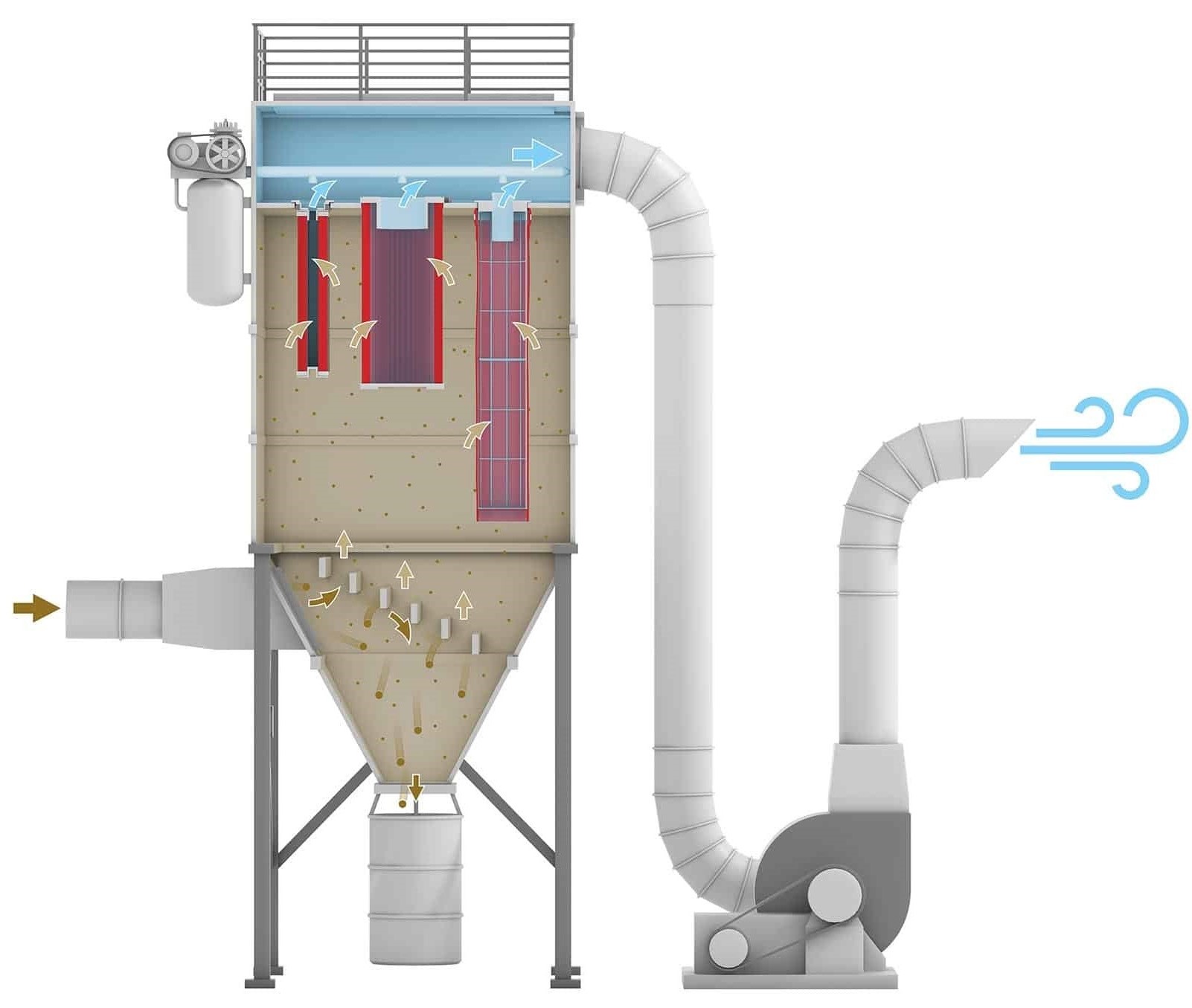

Dust Collection & Smoke Filtration

Many industries and manufacturing processes generate dust, such as grain mills, cement factories, sawmills, tobacco, chemical and food production sites. Some of this dust can be dangerous for humans and the environment, so regulations are becoming stricter to improve air quality in workshops and reduce emissions into the atmosphere.

Dust Filtration - Faced with mentioned challenges, it is becoming essential for industries to capture and treat them via dust removal systems. The efficiency and reliability of these systems depend mainly on the quality of their filtration components. Designed in different formats (filter bags, panel filters, cartridges, etc.), our dust collection filters are available in many types of media (polyester, PTFE, antistatic, etc.) to suit the treatment of each pollutant. Filtration Expert puts its expertise at your service to help you optimize and maintain your dust collectors.

Smoke & fumes Filtration - During metal and plastic processing operations (welding, engraving, laser cutting, etc.), the smoke and fumes released can be extremely harmful. To avoid the slightest risk, these fumes must be extracted and neutralized using quality filtration solutions available from us.

Compressed Air Filtration

Compressed air is an essential energy source for many industries. Whether it is used on construction sites or in production processes, it must be free of contaminants to preserve equipment, ensure product safety and meet environmental standards.

Dust, moisture, bacteria...; the ambient air used by the compressor is loaded with all kinds of contaminants. After compression, the concentration of these contaminants per m³ of air increases, causing greater damage.

Quality filtration is therefore essential to ensure dry and clean air. We deliver the most efficient and cost-effective filter elements, housings and air driers for compressed air and gas, engineered to provide lower pressure drop, longer filter life, easy element change-outs and more predictable maintenance.

Industrial Process Filtration

Liquids and steam are present in many industrial manufacturing sectors but also in the food and beverage industries. Each liquid has its own specific requirements depending on the purpose for which it is used, whether it is process water, chemicals or beverages for consumption.

From filtration of all kinds of beverages to filtration of food ingredients, our liquid filtration solutions will help preserve the integrity and safety of your products.

Our world class quality stainless-steel filter housings and elements provide excellent filtration and purification of steam necessary for food & beverage process plants to guarantee the protection of the installations.

Aviation Fuel Filtration

Jet fuel filtration is required at several stages, ensuring the highest standards of safety in aviation sector. We provide wide range of Horizontal and Vertical Filter Water Separator vessels with accessories & filter elements for static and mobile refueling applications. Filter water separators are two-stage vessels designed to remove dirt and separate water from fuel at refineries, product terminals, fuel farms and on refueling vehicles. They continuously coalesce and separate water, which collects in the vessel sump where it can be drained. Units qualified to military specifications are also available. This includes a complete range of filter cartridges (coalesce, separator and water barrier) qualified to the latest editions of EI specifications.